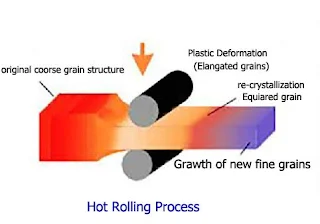

Hot working process

It is a process in which the material is heated above its re-crystallization temperature but below the melting temperature of the material. less amount of power is required for deforming the metal in hot working as compared to cold working.Re-crystallization temperature of Fe= 450°c

But the melting temperature is approx 1500°c

Cold working

The process of forming in which the metal is heated below its re-crystallization temperature is known as cold working. It gives less finished surface compared to hot working.E.g.- In cold working, Fe is heated below the 450°c.

Example- rolling at normal temperature,

Extrusion at normal temperature etc.

Advantage of hot working

- No strain hardening because the working temperature is above its re-crystallization temperature

- No chance of porosity in the material.

- As shear stress gets reduced at a higher temperature, therefore, less force is required for defamation purposes.

- Ductility and impact resistance are improved

- A very large workpiece can be deformed with reasonable size equipment.

- When course-sized grains are refined they result in a fine grain structure.

- Further stress removal process is not required.

- High reduction is possible without any fracture.

Disadvantage

- Due to high-temperature cooling handling of hot metal is costly and difficult

- Due to high temperature, there is a scaling of surface which leads to the poor surface finish of the finished product

- Close tolerance of dimensions is not possible

- Brittle material can't be hard work

- Metallurgical structure of workpiece may be non-uniform.

- example -hot rolling,hot extrusion,hot forging etc.

Advantages of cold working

- Increased strength

- Improved surface finish

- Controlled dimensional tolerance and concentricity

- Improved straightness

- Improved machinability

Disadvantages of cold working-

- Higher forces are required to initiate and complete the deformation

- Less ductility is available

- Intermediate anneals may be required to compensate for the loss of ductility that accompanies strain hardening

- Heavier and more powerful equipment is required

- Metal surfaces must be clean and scale-free

- Imparted directional properties may be detrimental

- Undesirable residual stresses may be produced

1 Comments

Add some more topic about mechanical engineering.

ReplyDeleteThank for Visiting our site

we will Happy to see you here again