Boiler mountings

1) Safety valve

2) Water level indicator

3) Pressure gauge

4) Fusible plug

5) Steam stop valve

6) Feed check valve

7) Blow-off valve

8) Safety valve

Type of safety valves are-

- Lever safety valve

- Spring-loaded safety valve

- High steam-low water safety valve

-

Safety valves are attached to the steam boiler chest.

- It is used to prevent an explosion due to excessive internal pressure. When the internal pressure inside the boiler exceeds its working pressures than the safety valves blow off the steam and maintains the internal pressure.

- Generally, two safety valves are present on a boiler.

Water level indicator

- The water level indicator is situated in front of the boiler in number two.

- it indicates the instantaneous level of water inside the boiler

Pressure gauge-

It may be of two type

- Analog pressure gauge

- Digital pressure gauge

- it is used to measure the instantaneous pressure of the boiler.

- it is also situated in front of the boiler

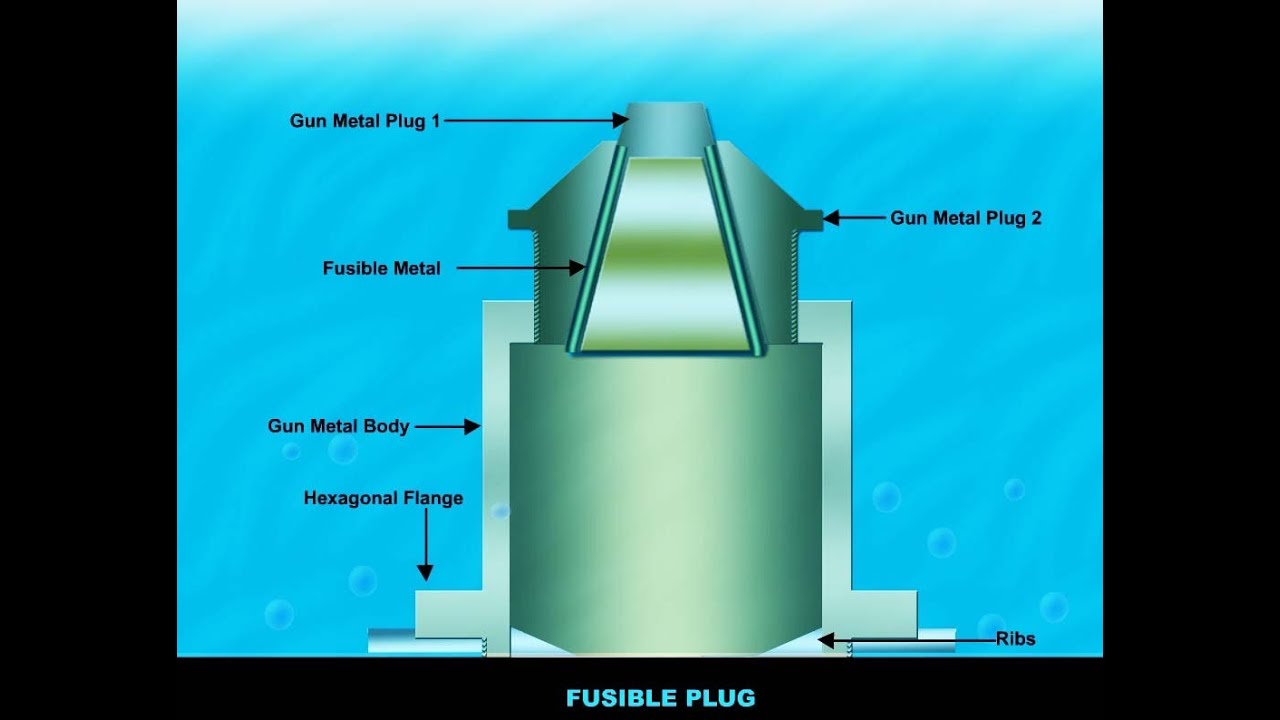

Fusible plug-

- Fusible Plug is a fitting used in Steam Boilers to enhance safety during operation.

- It is usually of brass, bronze or even gunmetal

- It’s working is dependent only on the temperatures not on pressures.

- When the water level goes below the fusible plug, the lead present inside the Fusible plug gets melted because of superheated steam, now the water from the boiler shell comes out and wets the flue gases

steam stop valve

- It is manually operated equipment used in the boiler.

- Fitted on top of the boiler body

- It may completely remove the steam from the boiler.

- It controls the flow of steam in the main pipe

Feed check valve-

- It is used to control the supply of water to the boiler

- It is used to prevent the escaping of water from the boiler when the pump pressure is less or the pump is stopped.

- It is fitted to the shell slightly below the normal water level of the boiler

- It regulates the supply of water which is pumped into the boiler by the feed pump.

blow off valve

- It is fitted at the bottom of the boiler drum.

- It is used to discharge the scale, mud, and sediments that get collected at the bottom of the boiler.

boiler accessories

- Air preheater

- Superheater

- Economizer

- Feed pump

Air preheater

- Air heater or air preheater is a waste heat recovery device in which the air on its way to the furnace is raised in temperature by utilizing the heat of the exhaust gases.

- It is installed between the economizer and the chimney.

- Tubular type

- Regenerative type air preheater

Superheater

- The steam generated by a simple boiler is generally wet or at the driest saturated.

- Steam superheater is a surface heat exchanger in which the wet steam is first dried at the same temperature and pressure and then raised to a temperature above the saturation temperature at constant pressure.

- The heat of flue gasses utilized in superheating the steam and as the superheater is placed in the path of the flue gasses.

Economizer

- It is used to heat the feedwater by the utilization of heat

- from the hot fuel gases before it leaves the chimney.

- An economizer improves the economy of the steam boilers.

Feed pump

The pressure inside a steaming boiler is high and so the feed water has to be raised in pressure before its entry can be affected in the boiler. The feed pump is a device which raised the pressure of water and forces it into the boiler or we can say that it is used to deliver water to the boiler

1 Comments

The pressure gauge must also have a siphon tube ( some times also called a pig`s tail ) between the boiler and the pressure gauge.

ReplyDeleteboiler cooling treatment service in Ontario

Thank for Visiting our site

we will Happy to see you here again