Type of manufacturing system

Flow shops or continuous manufacturing system

- Continuous manufacturing systems are designed to enable the mass production of a single product with a special-purpose machine.

- This system can have high production rates.

- The product goes through an assembly line with different stations where parts are added or worked on a little further.

- The skill level of the laborer tends to be lower than in production job shop

- The material flow is through a sequence of operations by material handling devices.

- This type of production system is ideal when a company has very high volume targets since it reduces the unit cost of the product.

- The time the item spends in each station or location is fixed and equal.

- The workstations are arranged in line according to the processing sequence needed

problems in a streamlined flow

- Ensuring continuous flow

- Work/Capacity Balancing

- Importance of Maintenance Management

- Good Quality Assurance System

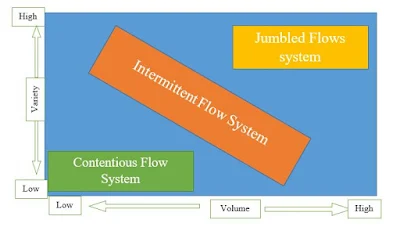

Intermittent Manufacturing System

- The intermittent manufacturing system permits companies to make different types of goods using the same production line.

- The manufacturing facility is designed to handle different product sizes and requirements. Generally, the goods are processed in batches to fulfill orders.

- This system is commonly referred to as a “job shop” due to its popularity in countries with relatively cheap labor making products for multinationals based thousands of miles away.

- The goods made using this manufacturing method are produced in small quantities, so they may not be suitable for stock. Customization is typically done post-purchase.

- This type of system is designed for production runs that happen intermittently, hence the name, or products that don’t require high volumes.

- It uses general-purpose machines and requires highly skilled labor.

Feature of Intermittent Manufacturing System

- Characterized by mid-volume, mid-variety products/services

- Increases the flow complexities

- Flow and capacity balancing are difficult but important

- Batch Processing

- Alternative methods of work organization

- Capacity Estimation is hard

- Production Planning & Control is complex

Flexible Manufacturing Systems or jumbled manufacturing-

- Flexible manufacturing is a modern manufacturing system that has become very popular.

- An FMS integrates all major elements of manufacturing into a highly automated system

- It involves a significant investment in machinery, although it reduces labor costs by implementing robots eschewing human labor altogether.

- These machines can easily be reconfigured to manufacture different products in different quantities, and the whole process is automatic.

- This method is called flexible manufacturing due to the flexibility in the variety of high-volume goods it can produce.

- In this process major capital investment and efficient machine utilization are essential.

- Due to the automated process, quality control is a lot easier, and unit costs are low.

Advantages of FMS

- Parts can be produced randomly in batch sizes, as small as one, and at a lower cost.

- The lead times required for product changes are shorter.

- Labour and inventories are reduced.

- Production is more reliable because the system is self-correcting and so product quality is uniform.

- Increased machine utilization.

- Fewer machines required.

- Reduced factory floor space.

- Greater responsiveness to change

0 Comments

Thank for Visiting our site

we will Happy to see you here again