Additive Manufacturing

Introduction

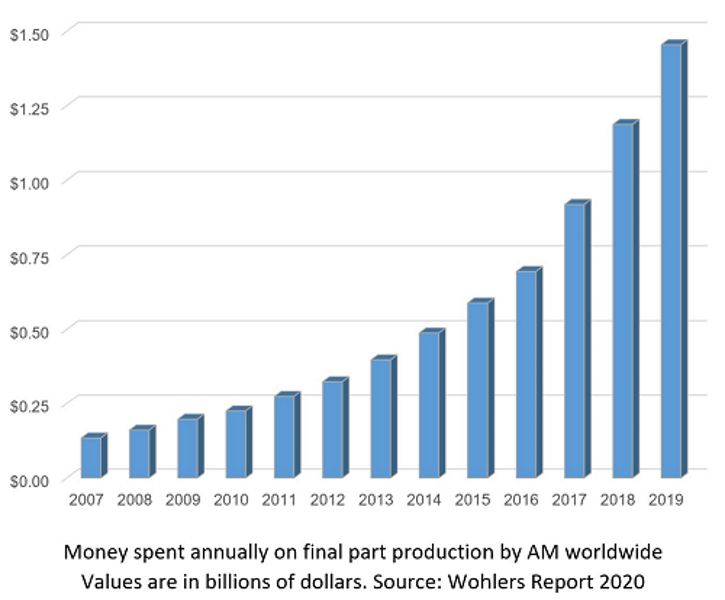

Additive manufacturing (AM), also referred to as 3D printing and rapid manufacturing, is a layer-by-layer the technique of producing three-dimensional (3D) objects directly from a CAD model. Unlike conventional subtractive processes that remove material by cutting from a larger workpiece, AM builds a finished piece in successive layers, each one adhering to the previous. Since its emergence 25 years ago, additive manufacturing has found applications in industries ranging from aerospace to dentistry and orthodontics. Across all industries, the AM industry is growing at the rate of 25 percent and it is forecasted to reach $17 billion by 2020. Enterprise AM will realize in the next 2-3 years while it takes 5-10 years for consumer printing to evolve.

|

- Maturing and emerging applications of AM for series production Review of AM in the dental industry

- Commentary on seventy-seven early-stage investments valued at $1.1 billion

- Compilation of seventy-two industry partnerships from the past twelve months

- Expert reports from thirty-five countries

- Tables of systems, third-party materials, software tools, and emerging technologies

Applications

The variety of applications for parts made by additive manufacturing has grown significantly over the development of the industry’s records, fed in part by the introduction of new materials, incremental enhancements to existent materials, and advancements in system process controller, rate, expense, accuracy, and reliability. A few of characteristics dictate current and potential applications:

Small production runs.

Additive manufacturing techniques and materials tend to be more expensive than traditional counterparts for large production runs, and thus they are most competitive for applications where flexibility and fast product development cycles are needed. Examples markets include those for customized parts and small production of prototypes or fully custom products.

Small part size.

Presently, low build speeds and technical limitations tend to limit additive manufacturing to areas where relatively small parts, such as one cubic foot or below, are needed.

High-value products

Given its comparatively low build speeds and high materials costs, additive manufacturing competes well in high-value markets.

Products with high complexity.

The creation of some complicated shapes and geometric features is difficult, if not difficult, to achieve using traditional methods. Additive manufacturing is more antagonistic where part complexity is acceptable because any part that can be formed digitally can be built with little or no additional cost related to complexity. It is also possible to use AM to consolidate several parts without the need for assemblage.

Elimination of tooling.

Any time apart, or a batch of parts, can be manufactured without tooling, substantial savings are possible. This usually occurs in situations.

0 Comments

Thank for Visiting our site

we will Happy to see you here again